Istanbul - Groz Beckert has officially launched its Productivity Benchmark, a new system to help its customers better understand how the different settings on a knitting machine and the use of certain elements and ancillary equipment can have a drastic effect on machine efficiency while also helping to reduce operating costs.

Istanbul - Groz Beckert has officially launched its Productivity Benchmark, a new system to help its customers better understand how the different settings on a knitting machine and the use of certain elements and ancillary equipment can have a drastic effect on machine efficiency while also helping to reduce operating costs.

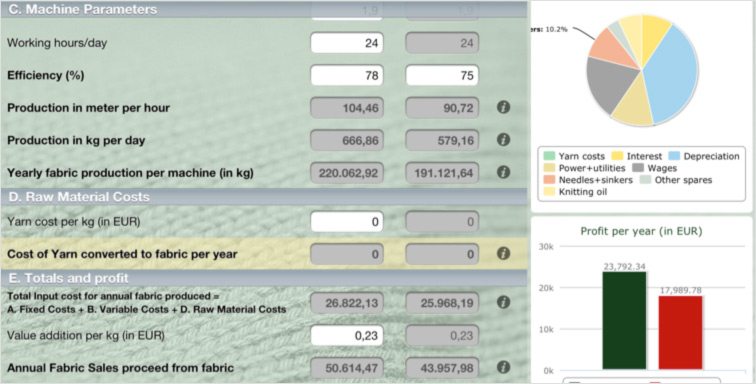

As reported by Knitting Trade Journal in May, the system shows how making small changes and adjustments to parameters such as machine rpm, oil usage and needle types etc. can significantly impact a company?s overall output and profitability over the course of a 12 month period. ?Anybody can sell a needle,? explained Groz Beckert?s Edelgard Keinath told Knitting Trade Journal. ?But this is an added level of customer service. It is minimal changes for maximum effect.?

For instance, increasing a machine's speed by just one revolution ? from 30 to 31 rpm ? over the course of one year already means a productivity increase of 7,000 kilograms. And the increase in productivity is accompanied by a reduction in running costs per kilogram of goods produced.

Once the questions have been answered the "Productivity Benchmark" collects factors like these and transforms them into a general overview for comparison purposes. Groz Beckert customers are then given precise information on what savings can be made if they tweak the settings on their machines or if they use a different needle product eg. switching to Litespeed needles or those with a conical hook.

The latter, for example, deals with issues such as when during knitting the hook, and especially the base of the hook, are subjected to high stresses ? e.g. by knots, slubs, double or multiple yarns. If the elasticity limit is exceeded the hook can bend or even break. The conical hook has an enlarged cross-section at the base of the hook and tapers continuously to the tip of the hook. This shape not only helps to strengthen and reinforce the hook but also increases the size of the hook interior. This particular geometry means a greater yarn clearance is created between the loop forming elements which allows both fancy yarns and poorer-quality yarns with slubs and knots to be processed without problems.

?The creation of high-quality, flawless knitted fabric is only possible using needles that have been optimally manufactured,? the company says. ?Precision and speed optimize the production process. This is where Groz-Beckert products come into their own, because it is only high-quality products with special features that enable the abovementioned factors to be changed in the first place. ?The unrivaled quality of Groz-Beckert products is reflected in their numerous benefits: absolutely smooth surfaces, advantageous geometry for gentle, trouble-free yarn gliding, high dimensional accuracy for an absolutely uniform loop structure, precise latch guidance for minimal wear, perfect loop cast-off without the risk of damage to the yarn, specially processed needle butt edges for reduced wear and smooth needle movement in the trick, conical hooks for higher hook stability combined with the largest possible hook interior, and litespeed design for reduced power and oil consumption ? to name but a few.?