Why Subscribe?

If you are a knitwear or knitted fabric manufacturer looking to source the latest knitting technology or a designer or retailer searching for inspiration in the field of knitted textiles, Knitting Trade Journal is the ideal resource for you.

Key benefits:

- Unrivalled expert industry coverage of the latest knitting technology and industry news.

- Exclusive bi-monthly printed magazine delivered to your door

- Unlimited access to Knitting Trade Journal online premium news and features

- Unlimited online access to eight years archived content

- Unlimited access to all digitised back-issues of Knitting Trade Journal

- Daily online news, comment and analysis

- Weekly e-news round-up of key developments

- Exclusive discounts on all MCL publications

You will learn about:

- All about the latest knitting technology as it is launched.

- Unique insight into thinking of knitting industry leaders.

- Details on the most innovative fibre and yarn developments.

- How new trade agreements will impact the knitting industry.

- Social compliance in knitwear sourcing destinations.

- Advice from experts on knitted fabric manufacturing.

- Examples of industry best practice in action.

- The inside track direct from journalists on the exhibition floor.

- Expert advice on raw material selection and product stewardship.

- Game-changing research and novel textile patents.

All this from MCL News & Media – the fastest growing international textile publisher – which offers a unique insight into how today’s industry will look tomorrow.

In print, online and mobile device formats.

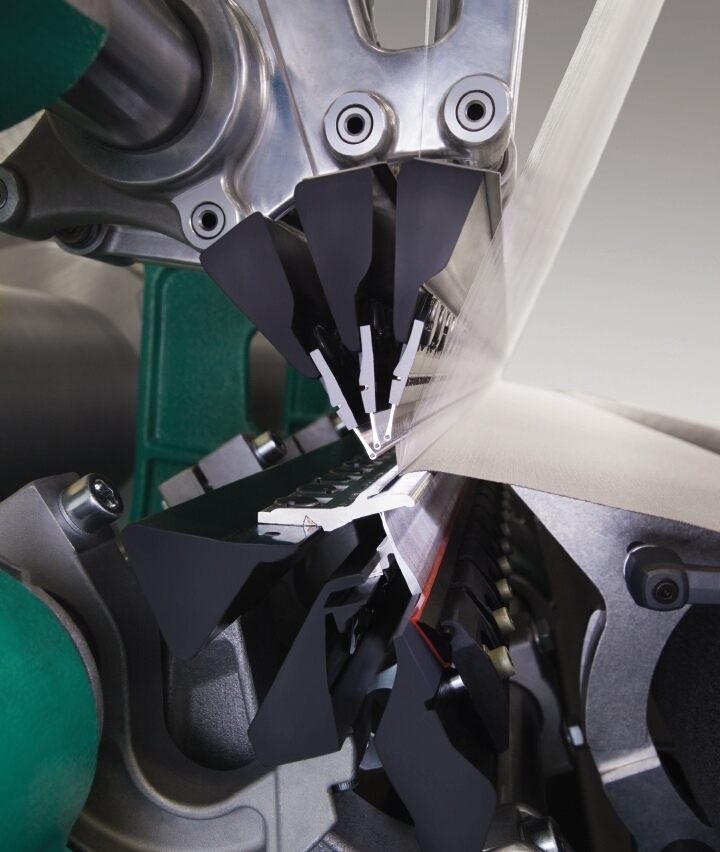

Obertshausen – Warp knititng builder Karl Mayer outlines how the use of carbon fibre reinforced plastic (CFRP) in warp knitting machines helps reduces energy consumption.

Obertshausen – Warp knititng builder Karl Mayer outlines how the use of carbon fibre reinforced plastic (CFRP) in warp knitting machines helps reduces energy consumption.