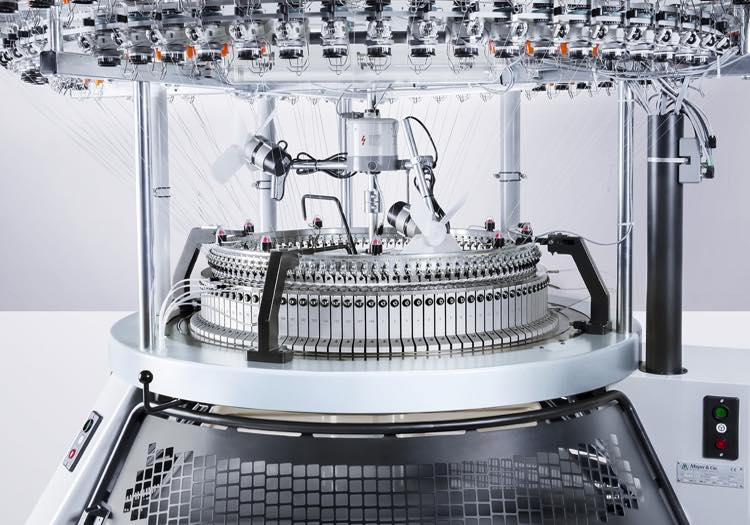

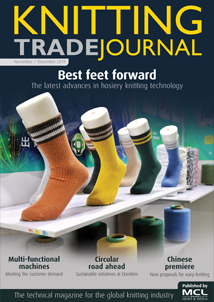

Albstadt - Mayer & Cie will launch a new Relanit model, developed specifically for the Chinese market, at the upcoming Shanghaitex trade fair.

Scheduled for 27 to 30 November 2017 in Pudong, Shanghai, the German circular knitting machine manufacturer will be showcasing the Relanit 3.2 SC which, with a knitting head manufactured at the company's Albstadt headquarters in Germany, completes it assembly at the firm's Chinese facility.

The company’s Shanghaitex booth will also include an information stand about spinitsystems, Mayer & Cie.’s new spinning and knitting technology.

“The Relanit is one of the best known and most popular Mayer & Cie machine ranges,” says Wolfgang Müller, Sales Director at Mayer & Cie. “With the Relanit 3.2 SC, which we are presenting to our local customers in Pudong, we have now aligned our successful model to the special needs of the Chinese market.”

The Relanit 3.2 SC is assembled at Mayer & Cie’s works in Shanghai. It incorporates locally made components while the knitting head is manufactured as a matter of principle at Mayer & Cie’s main factory in Germany.

As the company notes, the quality of the knitting head largely determines the quality of the fabric that will be knitted on the machine. At the same time, local final assembly increases the flexibility and speed at which local orders can be handled. “In this way we can offer selected machine types in the price-sensitive Chinese market at a competitive price – machines like the new Relanit 3.2 SC,” says Müller, explaining the approach that Mayer & Cie describes as the knitting head principle. It is a principle that the company has used for a number of years with its MSC 3.2 II and MDC 2.2 models. Both the Single Jersey and the Double Jersey machine are very popular with Chinese customers.

In its technology and design the Relanit 3.2 SC, which will now go on sale in China at Shanghaitex, resembles the Relanit 3.2 S. Essentially this means it offers all of the well-known benefits of the Relanit range including high productivity and process reliability.

According to Mayer & Cie, the Relanit 3.2 SC delivers a constantly high knitwear quality with no loss of productivity even when processing difficult or thicker yarn qualities. With a 30 ins diameter, the Relanit 3.2 SC reaches speeds of up to 40 rpm. It also uses significantly less energy than conventional machines, the company says.

The Relanit 3.2 SC is suitable for a wide range of uses. Although the Relanit’s traditional speciality is processing cotton, such as for sports and leisure outerwear or for nightwear and underwear, it is said to be equally well suited for the manufacture of fabrics for the automotive industry or for home textiles.

With its wide range of benefits, the Relanit is popular with customers, especially in countries that process large quantities of cotton. Since its market launch 30 years ago Mayer & Cie has sold more than 10,000 Relanit machines. Every year, a around a further 300 new Relanit machines are delivered to customers.

The first Relanit machines were presented at the 1987 ITMA in Paris. They made – and still make – use of Mayer & Cie’s then patented relative technology. With this technology, the sinker moves towards the needle, relatively speaking. This means fewer deflection points the yarn has to travel to form a stitch and each deflection means less stress on the yarn.

The result, says Mayer & Cie, is that Relanit can process difficult yarn or inferior qualities without a hitch. This means not only in creating fabric of a certain quality but also without making amends in terms of production speed or machine downtimes.

The company points out that both would be the case if inferior quality yarn were to be processed on a conventional machine and because yarn is the key cost factor in knitting, Relanit can therefore help the knitter to save a lot of money and thereby increase profits.

“What our Chinese customers will get with the Relanit 3.2 SC is a machine that is well thought out and tried and tested thousands of times,” Müller says. “They are buying a successful model at a very attractive price.”

The Mayer & Cie. trade fair booth at Shanghaitex will also include an info stand about the spinitsystems spinning and knitting technology. The company will explain how its Spinit 3.0 E, a machine that also uses relative technology, ensures that the roving, a fragile bundle of fibre, can be knitted on a machine that combines spinning, cleaning and knitting in a single model.