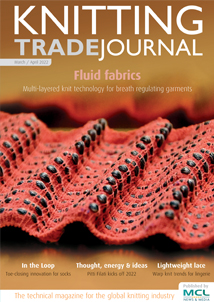

Brescia - Santoni has launched a new fabric production process that takes advantage of the company's circular knitting machine technology and transforms circular knitted mesh into a linear fabric.

This new process, known as K-Fabric Revolution, enables the production of superfine gauges as well as providing a natural bi-stretch effect without adding elastic yarns. It also enables the knitting of jacquard patterns of any dimension, complexity and placement.

Samples from the K-Fabric Revolution project demonstrating the technology's high-quality and economic benefits will be on show at the upcoming ISPO exhibition in Munich. "Thanks to the optimization of the supply chain – from the idea to production, passing through the prototype and the sample - the K-Fabric revolution process meets the modern fashion market’s demand of customized and fast production cycles," says Santoni. "Using seamless production flexibility even for the luxury industry, it basically makes possible the creation of new potentially revolutionary items."

Further benefits of the K-Fabric process also allows a straightforward way to use a mixture of fibres as well as a fast and sustainable production of small quantities. The production process can be carried out on range of different different Santoni machines which are able to produce the tubular fabric. Then, using a special laminating machine, Santoni melts adhesive fabric onto the seamless products and the tubular fabric is laminated with a membrane. At the end of the cycle, a slitting device cuts the tubular garment to hand the operator a finished open width fabric - essentially transforming the circular knitted mesh into linear fabric.

"The possibility to transform circular knitted mesh into linear fabric makes K-Fabric revolution process the new manufacturing paradigm par excellence, in order to answer both to the rising production demand of the luxury sector, the changes in the supply chain model and the search for new materials," Santoni says.

At ISPO, Santoni will also present some of its latest seamless knitting machine developments.

At ISPO, Santoni will also present some of its latest seamless knitting machine developments.

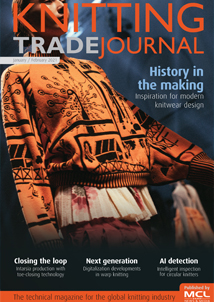

On show will be the X-Machine, Santoni's 4-feed knitting machine which uses sock knitting processes and concepts to produce seamless shoe uppers, characterized by countless intarsia patterns, including three-dimensional areas and eyelets for the laces.

Using its mapping system, X-Machine can select different areas according to the type of yarn used and the various combinations chosen producing an upper that is ready for the application of the sole.

"With the help of this machine, the production process becomes more efficient, reliable and economical," says Santoni.

Also on show will be two seamless knitting machines for the textile clothing sector.

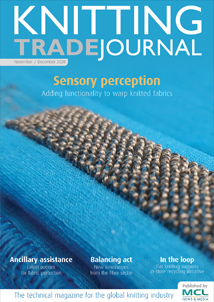

The SM8-TOP2V, for example, uses 40G seamless technology to knit comfortable garments, which provide the customer with a second-skin effect. Thanks to the garment’s elasticity and positioning of special supporting areas, the final product can offer both protection and support to the body. Moreover, the ability to create breathable and thermoregulated areas allows the release or retention of body heat.

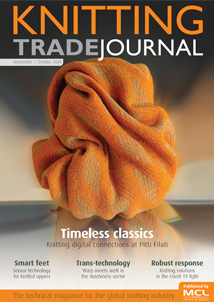

The sportswear sector will also be able to examine the latest version of the SM8-TR1. This machine is capable of creating sportswear items that are remarkable for their fineness and lightness; items knitted with natural yarns give a soft and pleasant touch as well as offering superior comfort. SM8-TR1 technology also allows knitting mills to create body-map mesh, breathable and compression areas.

At ISPO, Santoni can be found at Booth 410 in Hall A5

www.santoni.com

www.lonati.com