Seoul – Hyosung says that brand interest in its GRS-certified recycled nylon yarns made from pre-consumer waste is growing as it also continues to explore new ways to use post-consumer waste to make its yarns.

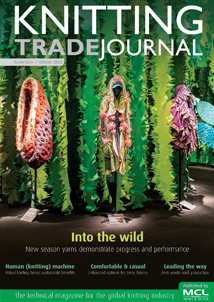

Brands such as Fat Face and Osprey are now using Hyosung recycled nylon in their swimwear and back packs and the Korean fibre supplier has also set up an arrangement with Lenzing to capitalise on comfort and athleisure clothing that’s boomed since the start of the pandemic with people working from home.

“Regarding recycled nylon made with post-consumer waste, the industry is asking for a story similar to that of polyester, where the re-use of (post-consumer) PET bottles demonstrates a clear benefit,” says Mike Simko, global marketing director for textiles at the south Korean fibre giant.

But, as Simko alludes to, there are still some tough technical challenges to overcome before it can provide recycled yarns made from this type of waste.

Hyosung’s Mipan regen range of 100 per cent recycled nylon yarns has been on the market for a few years now – first launching at Interfiliere back in 2009. It’s still made using 100 per cent post industrial waste as opposed to post-consumer materials – given the technical difficulties that still need to be overcome with the collection of reliable raw materials of the necessary quality.

But the company says it’s a problem that it’s working on and something that its customers want.

“It’s difficult and expensive to get suitable raw material for recycled nylon made with post-consumer waste,” admitted Simko. “And many brands and retailers have accepted the use of industrial waste as it has clear benefits on decreasing GHGs and reducing dependence on non-renewable petroleum-based raw materials.

“Having said that, Hyosung continues to explore options for post-consumer recycled nylon.”

Simko says the biggest challenges are collecting and sorting the material waste and cleaning up the contaminants and impurities. “This can be how to separate different garment types or even how to separate different fibres, finishes and trim in a given garment,” he said. “Even with larger scale items like fishing nets, carpets or industrial waste, contaminants will be present and have to be managed. Again, polyester has an advantage with the large amount of PET bottles available, and the relatively low amount of contaminant and impurities that need to be managed.”

That hasn’t stopped brands from using its pre-industrial recycled nylon in their collections though, and Hyosung launched its ‘regen robic’ 100 per cent recycled multi-performance high tenacity nylon fibres and a 100 per cent recycled elastane made from pre-consumer waste at ISPO Munich, last year.

“With Mipan regen robic being the first high tenacity nylon in the market we have had great interest and adoptions from pack makers like Osprey,” says Simko. “Similarly, our 100 per cent recycled content, ‘Creora regen’ spandex maximises waste reduction rather than blending it with virgin polymer. Whether it is our spandex, our nylon, or our polyester, all of our regen yarns are made with 100 per cent reclaimed waste and are GRS certified.”

The company has recently teamed up with man-made cellulosic fibre supplier Lenzing to take advantage of the move to more casual garments being worn by people at home during trhe pandemic. “While we still have some lockdowns, we see the emergence from these as one where we take our comfort and wellness experiences outside the home … Lenzing was a logical partner as it’s a leading fibres suppler of wood-based materials (viscose, lyocell), which match up with Hyosung’s portfolio of performance fibres.”

Earlier this month, Hyosung confirmed it would build a factory with a capacity of 15,000 tons a year in Cerkezkoy, close to Istanbul, Turkey, by investing 60 billion won (US$54 M) by July next year. Upon completion of the factory, the company’s spandex production capacity in Turkey will increase to about 40,000 tons a year.