Knitting Trade Journal talks to Beatrice Lederer, managing director at Lederer Elastic Yarns, about the company's latest developments and how it has responded to the key trends currently driving the industry.

Knitting Trade Journal: Can you tell our readers a little bit about the history of Lederer Elastic Yarns?

Beatrice Lederer: Lederer Elastic Yarns was founded in 1948 by our grandfather Jörg Lederer in Amstetten (Baden-Württemberg). From the very beginning, only covered elastic yarns were produced which were suitable for a wide range of applications - from fashionable legwear (hosiery /socks) to woven fabrics and medical products (compression sector) supplying renowned manufacturers throughout Europe. The use of state-of-the-art technologies and the processing of high-quality materials form the basis of our yarn production. It is our intention to provide every customer with the greatest possible support; this, coupled with our decades of expertise, makes us an expert and reliable partner in yarn development and production.

Beatrice Lederer: Lederer Elastic Yarns was founded in 1948 by our grandfather Jörg Lederer in Amstetten (Baden-Württemberg). From the very beginning, only covered elastic yarns were produced which were suitable for a wide range of applications - from fashionable legwear (hosiery /socks) to woven fabrics and medical products (compression sector) supplying renowned manufacturers throughout Europe. The use of state-of-the-art technologies and the processing of high-quality materials form the basis of our yarn production. It is our intention to provide every customer with the greatest possible support; this, coupled with our decades of expertise, makes us an expert and reliable partner in yarn development and production.

KTJ: What is your core product offering and what the main application areas for your products?

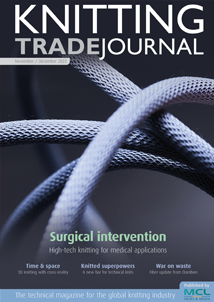

BL: Medical products have become more and more important. For example, they offer antibacterial and anti-odour features. In addition, by using certain technologies, we achieve accurate determination of compression, which is very important.

In the fine hosiery sector, we focus very strongly on the feel of the raw materials, so that our yarns impart a silky soft feel in the end product.

KTJ: Can you outline some of the key advantages of Lederer technology?

BL: We have a very large and versatile machinery park and are constantly working to improve our technologies. We are able to configure the set up of our production to meet the required specifications for our yarns. Our development department consists of a young, dynamic team paired with colleagues who have years of experience in the field of elastic covered yarns. This combination is unbeatable when it comes to developing new innovative yarns for our customers.

KTJ: Which market sectors, such as medical hosiery or knitwear for example, are showing the greatest demand at the moment and which sectors have the greatest potential for further growth for Lederer?

BL: We are currently experiencing increased demand in the area of medical yarns. There, as well as in the outdoor and sportswear sector, we see great potential for the future.

KTJ: I noticed that Lederer has invested in a new centre for medical products. Can you tell our readers a bit more about this project?

KTJ: I noticed that Lederer has invested in a new centre for medical products. Can you tell our readers a bit more about this project?

BL: We have bought eleven new covering machines in the last two years. These new machines open up almost unlimited possibilities in yarn production for the medical sector, which is our key market of the future. Developments can be tested and produced faster on the new machines for medical yarns, which also shortens delivery times.

KTJ: Customization is a key trend in the textile industry these days. Does Lederer work with customers who come to you with specific requests?

BL: Yes, definitely. Our customers often approach us with specific requirements for yarns. In the first step, we advise our customers on possible raw material combinations and then produce small sample quantities for testing. Fortunately, this can be implemented in a short time thanks to our in-house development department.

KTJ: How has Lederer responded to some of the key trends that have appeared in sector over the last few years such as sustainability, for example?

BL: Because sustainability is in demand especially in the fashion and activewear sectors, we have also taken over some machines from our former competitor Swisslastic, with which we will increasingly produce elastic covered yarns with natural fibres. In that way we are able to respond to current market trends.

The older machines are being converted in-house to energy-saving IE3 motors and frequency control. In addition, all production halls and warehouses have been converted to LED lighting in recent years.

95% of Lederer’s work is with European suppliers, including some from Germany, in order to shorten transport routes.

We recently achieved our GRS certification and from now on, depending on our customers’ needs, we can have our yarns certified. This allows us to offer traceability of the recycled content throughout the supply chain. Furthermore, we offer our customers the option to wrap the yarns in recycled paper. The waste (yarn remnants) is downcycled by turning it into cleaning cloths and filling materials.

KTJ: The impact of the Coronavirus has been felt across the industry. How has Lederer managed its activities during the last 12 months?

BL: More than ever, the Corona crisis has shown us how unstable the market for the fine hosiery sector is. We therefore focused strongly on the medical sector. In the meantime, we also had strong demand for yarns for mask production.

In addition, we used the second half of the year to integrate the new machines into our production and to adjust the articles accordingly to ensure a smooth transition.

KTJ: Do you see any other challenges facing the industry at the moment and what challenges do you anticipate over the next few years?

BL: The Corona crisis is still present and has a strong impact on the whole industry. Price increases in raw materials and transport are the consequence that we are all struggling with right now. In addition to all the challenges, we also see the opportunity in strengthening our location in Germany again. Short supply chains and material sourcing within Europe are gaining in importance.

KTJ: As applications and fields of use broaden for elastic yarns, how will Lederer continue to work to gain market share and differentiate itself from the competition?

BL: We work very successfully with institutes to research new applications for elastic covered yarns. This way we are always up to date with future trends and can develop new products together with innovative partners.