Brescia - New product launches, investments in the manufacturing process and upgrades to the day-to-day operations have laid the foundations for a strong and secure future at Busi Giovanni.

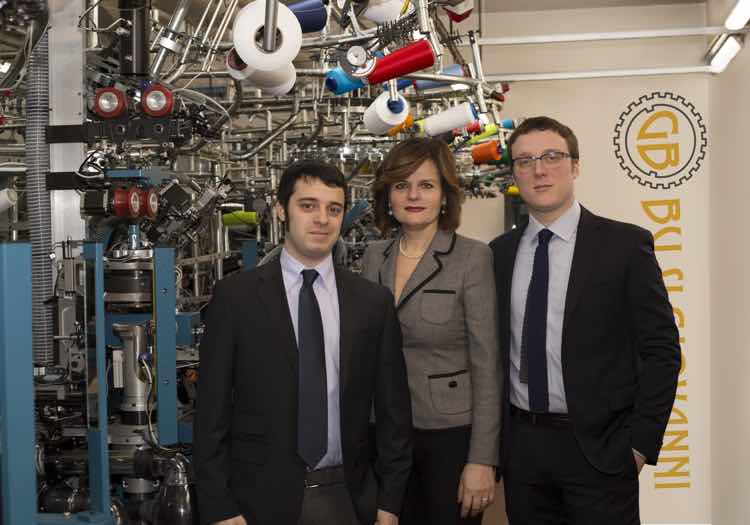

Sitting across the desk from Catina Busi and Michele Castagna, respectively General Manager and Export & Marketing Manager, at the Brescia headquarters of the hosiery knitting machine manufacturer Busi, there's a light-hearted pause in our conversation as we contemplate the company's next milestone.

Celebrating its 60-year anniversary in 2018, at first we discuss how recent investments and upgrades to the day-to-day operations at the company have laid the foundations for the foreseeable future. The conclusion we come to, however, with the new generation of the family now in place, is that there's no obvious reason why this innovative knitting technology firm won't flourish for the next 40 years, taking it to that remarkable 100-year anniversary.

As most in our industry will be aware, this new generation, Leonardo and Francesco Busi, the two sons of the late Gianmario Busi, had their roles within the company somewhat thrust upon them following the tragic passing of their father and their grandfather and company founder, Giovanni Busi, in June 2017.

Still, as their aunt, Catina Busi, points out, both sons have risen to the challenge, with Leonardo taking on the role of Technical Manager and Francesco working on the company's vital software systems. This, coupled with a reorganization of the factory production systems and an extremely healthy order book means the company is in as strong a position as ever.

"Over the past two or three years we have had a lot of spontaneous requests coming from different parts of the market," says Mr Castagna. "This is the result of years of hard work and marketing dedication by Busi. Across emerging markets in Asia, Eastern Europe and Africa, word of mouth has spread the Busi reputation and we are now steadily benefitting from this."

Medical

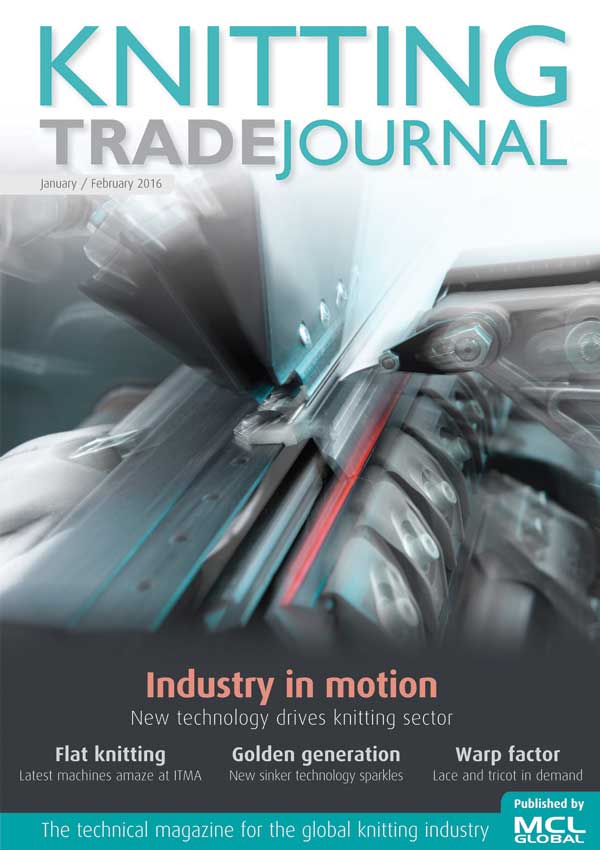

A key focus at the moment for Busi includes the preparation for next year's ITMA exhibition in Barcelona. At the show, Busi will demonstrate its now complete range of medical hosiery machines, including the 4, 4 ½ and 5 inches diameter models on both the Busi Medical and the Busi Medical Terry, while the Rimaglio toe-closing device is available for each diameter and gauge, with up to 400 needles for the 5 inches.

Busi Medical is a high production single cylinder knitting machine, equipped with dial needles for the production of medical compression socks in Compression Classes 1, 2 and 3. This is the only medical machine in the market able to knit true rib, as well as embroidery patterns in 5 colours plus the ground. The machine is equipped with full electronic control and features two feeds, for plain and rib fabric, as well two more feeds for inlaying the elastic. A sandwich terry option is available on the Terry version only.

The compression graduation is achieved both through the automatic stiffening that can be activated on all step motors the machine is equipped with, and by managing the elastic tension and quantity fed into the machine.

Needle selection is performed by nine piezoelectric actuators that allow the machine to knit plain or rib fabric in 1x1, 3x1, 5x1, etc. and embroidery patterns on a mock rib base with 5 colours per course plus the ground with elastic in one feed.

It can also knit embroidery patterns on a mock rib base with 1 colour per course plus the ground, with elastic in two feeds, as well as floated yarn mesh patterns in two feeds on a plain base or mock rib base with elastic.

Also boosting the appeal of the medical range has been the company's new fashion designer who, using the machine's enhanced patterning and colour capabilities, can demonstrate to customers the multiple variations on offer. "Traditionally, medical compression hosiery was dull and unattractive: just a merely functional item," explains Catina Busi. "Now, thanks to our Busi Medical and Busi Medical Terry, consumers can purchase a wide variety of attractive, colourful and aesthetically pleasing medical hosiery. Our new hosiery designer can enhance regular machines and also teach the medical-sock makers how to create colourful, cheerful products."

Such has been the success of these machines, Busi is continuing to work closely with customers such as France’s Gibaud, which produces collections of aesthetically pleasing medical socks, entirely on the Busi Medical, and while Gibaud continues to add to its bank of machines, Busi is also working very closely with other major medical hosiery manufacturers in Germany and France.

As well as these traditional markets for medical hosiery, Busi is also fielding increasing numbers of enquires from markets where, in the past, medical hosiery has not been in demand. "We have found that we are now receiving enquiries and orders from countries in which, even in the recent past, people hardly knew what a medical sock was," adds Mr Castagna. "There is growing interest from countries such as China and Taiwan, and we expect this trend to become a reality in other emerging markets, where there are increasing numbers of people having this requirement."

Key to securing these new customers, whether they are looking to source medical machines or models from any of Busi's other ranges, has been a combination of Busi's technological know-how and flexibility. Illustrating this, Mr Castagna explains how one hurdle in particular was overcome. "An issue for some customers was the dilemma of investing in Busi machines and adding them seamlessly to their existing bank of Lonati models. Here we worked closely with the customer, developing bridging software, which ensures that the customer can run, control and monitor their new Busi machines alongside their existing models, without any issues or problems whatsoever, using the same software on both types of machines.

"One of the mental obstacles for hosiery manufacturers looking to invest in new machines is getting over the fact that, if they already use Lonati machines, they must continue to do so. Now, the brand new Busi Control Tower, which includes production monitoring software, means that the controls and the software will be the same for both excellent ranges of Italian-made machines. For the customer, this adds value to both their new and their existing machines."

As well as developing new technology, there has also been investment in the day-to-day operations here in Botticino, near Brescia. A new Operations Manager, working closely with Leonardo Busi, is ensuring a highly efficient and extremely well-organised factory floor, whilst a new internal showroom is proving extremely popular for new and existing customers, keen to see Busi knitting machines in full-working order, while they discuss orders.

"Optimising the production processes and increasing sales are all contributing to a solid foundation for the future," Mr Castagna says. "This allows us to invest more and increase innovation in the factory, which helps our customers, in the end. The market in Italy and other parts of Europe is good for us and now Asian manufacturers are realising that they need to increase the quality level of their productions and they understand that the only way to go forward is to produce high quality products. If they want to upgrade their machines, Busi is the option."