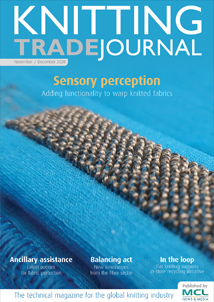

Paderborn - Penn Textile Solutions is opening up new applications for super-stretch textiles by using warp-knit fabrics from its dreamshape sport collection as the outer shell for sports, leisure and outdoorwear.

Combined with Trans-Textil's PFC-free membrane, lamination and surface finishing technology, Penn's partial 3D constructions enable the targeted placement of functional zones which means the final fabric is able to meet the highest requirements in terms of performance, design and ecology.

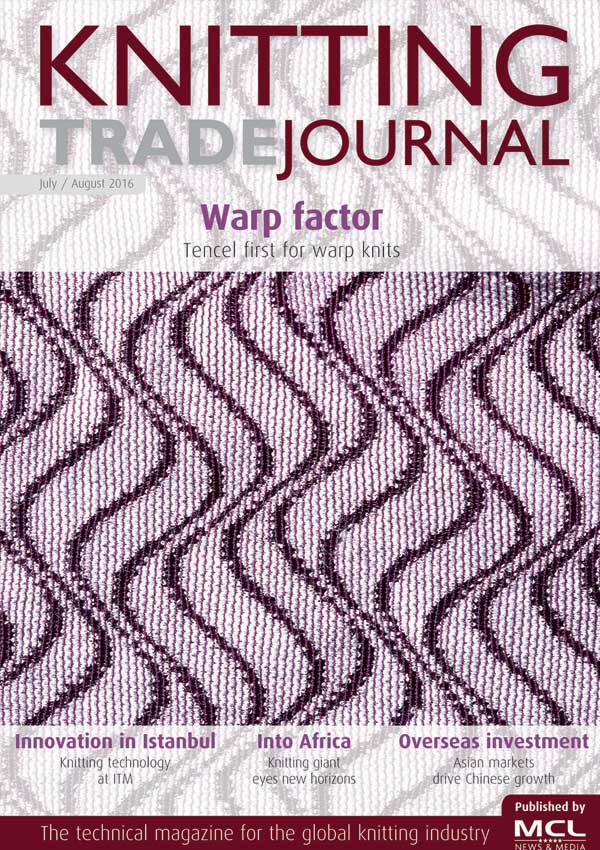

Penn's dreamshape technology combines various materials and warp patterns into a single, stretch, seamless warp-knitted fabric that meets the specific demands of differing areas of the body in sports situations.

This makes it possible to position breathable mesh and abrasion resistant zones precisely where they are needed in order to achieve climatic comfort and enhanced durability.

As the functional segmentaion is achieved as part of the actual warp-knitting process, this dispenses with additional seams, enabling optimised clothing construction and maximum freedom of movement. Reducing the number of seams also lowers the risk of leakage.

"Thanks to reduced friction, and use of fabrics incorporating elastane, the outfits accommodate every movement, even in cases of extreme exertion," the company says. "This function also enables an exceptional, modern and technical design idiom for individualization and styling in line with customer demands."

Functional hybrid systems

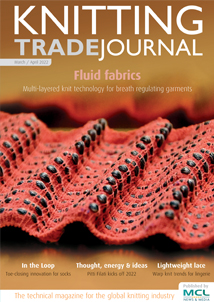

In the multi-layer laminate, Trans-Textil's membrane systems are designed to ensure reliable impermeability, and in connection with the warp-knit fabric's partial 3D constructions, deliver breathability where it is required. The superstretch materials are processed using Trans-Textil's unique Point-in-Point lamination technology in which a grid of PU hotmelt adhesive dots is applied in an evenly spaced and precisely controlled process, adapted to the material combination.

This not only ensures robust and durable processing and maximum breathability but also enables a four-way stretch effect for optimal ergonomics and freedom of movement. The result is a functional high-performance hardshell laminate that resembles a midlayer in terms of its high elasticity and soft feel, the company says.

Trans-Textil also has an option of transparent or coloured membrane systems for the 3-layer laminate to enhance design options. In combination with a coloured lining or one with a design applied in the eco-friendly transfer printing process, this delivers can deliver a range of colour sections with an open knit structure.

All the materials including the Topaz membrane systems are certified to the Oeko-Tex Standard 100 and are processed in Germany in conformity with REACH. PFC-free formulations from the Topaz Clean4Green line are used for the water-repellent surface finish.