Aachen - The Institute of Textile Technology at RWTH Aachen University has begun exploring the wide range of technical textiles that can be produced on its new Biaxtronic Co, high performance warp knitting machine.

Technical textiles play a central role in all areas and application fields of the ITA. Between 1999 and 2011 the ITA Construction Composites research group developed more than 500 textile reinforcement structures for concrete structures with the help of the technology from Karl Mayer Malimo.

Now, following the 2020 procurement of the latest high-performance warp knitting machine which is equipped with a course-oriented weft-insertion system, the institution is now looking to further develop reinforcement structures for concrete matrices.

Textile reinforcements in concrete do not require any corrosion-related covering and therefore make building cheaper, more environmentally friendly and more versatile. These completely new architectural solutions can be implemented through the slender construction forms of textile concrete.

The ITA is now conducting a range of research and development to see what is actually possible.

Between 1999 and 2011, the Construction Composites Research Group developed textile reinforcement structures for concrete structures as part of the Collaborative Research Centre 532. The work was carried out on the Malimo machine, and then continued at the ITA after 2011. However, recent textile projects placed high demands on machine technology and required new investments. Once again, the ITA opted for a model from Karl Mayer. “The Malimo was already a great machine. Unfortunately, it was just getting on a bit,” says Martin Scheurer from the Department of Textile Machinery and ITA, when explaining their choice.

Completely assembled and functionally tested in advance at Karl Mayer Technische Textilien in Chemnitz, this tailor made, high-performance warp knitting machine with course-oriented weft-insertion is also equipped with a number of new functions that will open up new research paths for the ITA and its research partners.

Made-to-measure

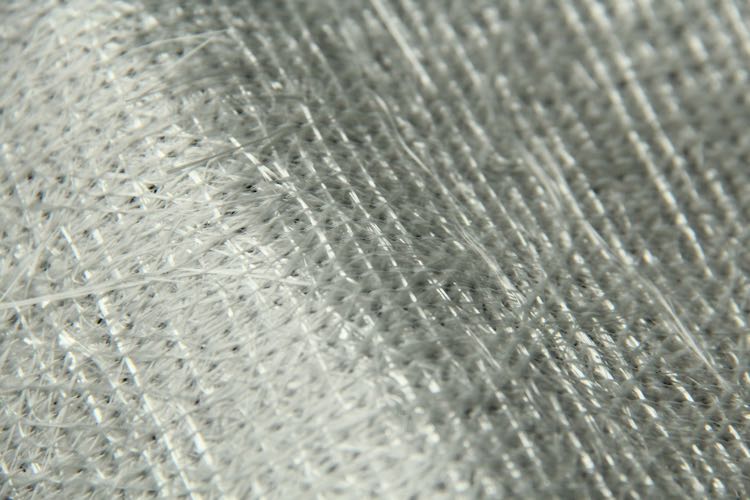

Biaxtronic Co is suited for the production of biaxial non-crimp fabrics and composite structures, and is equipped with specific features for its use at the ITA.

One of these is Kamcos 2, the latest generation of Karl Mayer’s Command System which offers an ethernet interface for integrating the machine into an existing network. This enables participation in future-oriented research topics such as Industry 4.0, inline quality control, sociology and process chain networking.

“We are planning to transmit the data from the producing machine via ethernet to the Internet of Production Excellence Cluster at RWTH Aachen University. The cluster deals with production research in high-wage countries,” says Scheurer.

The Biaxtronic Co for the research facility was also equipped with an EL pattern drive. The electronic guide bar control and the ability to vary process parameters online contributes to the production of locally adapted, tailor-made textiles. Furthermore, the product quality can also be significantly improved. For example, Scheurer wants to use the EL drive to investigate the influence of the warp knitting thread in different lapping variants on the geometry of the roving used and therefore on the behaviour of the finished grid structure.

Other details that favoured the Biaxtronic Co are a working width that meets standard industrial practices and the possibility of feeding basic substrates such as nonwovens in a standard process.

With the new machine, ITA researchers also want to further develop and produce reinforcement structures for concrete matrices. Functional models and prototypes for other areas of application are also to be produced on the machine. Fore example, reinforcements for wound dressings and hybrid warp knitted fabrics on a nonwoven substrate.

The combination of grid structures with other materials also facilitates fundamental research into geotextile applications. Projects for filtration technology can also be implemented while the production of unidirectional (UD) non-crimp fabrics for fibre composites and of flat warp knitted fabrics for heating textiles, which can be used in the mobility sector, are also possible.

In addition to research and development work, the ITA has its sights set on production practice using the Biaxtronic Co. Users of weft-insertion machines can use the capacities and expertise in Aachen to optimise their production processes, produce prototypes of new textile structures or even test the processing of new materials.

Interested parties can find out what can be done with the Biaxtronic Co on 29 April 2021 with the ITA inviting interested parties to discover the new machine as part of a one-day industrial event. “We look forward to exchanging information with industry and research partners from all over the world,” says Scheurer, adding that he is looking forward to stimulating discussions on the needs and future developments relating to companies in the manufacturing sector in particular.

The procurement of the Biaxtronic Co was funded by the German Research Foundation (DFG) and the State of North Rhine-Westphalia under project number INST 222/1264-1 FUGG.