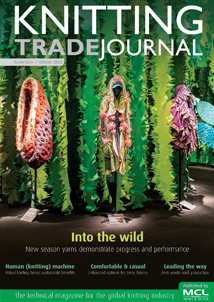

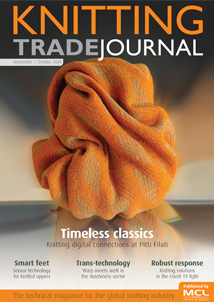

Varese - Italian warp knitter Eurojersey has unveiled its new Autumn Winter 2023 collection of Sensitive fabrics for the lingerie sector.

Under the theme “Fairy Core”, the new collection offers proposals for eclectic lingerie, "a synthesis of a fantastical journey that adds that sense of magic to everyday life", the company said. "An aesthetic, enchantingly impetuous and happy as fairies in another world, it combines seduction and sophistication through a declination of nuances from the coolest and lunar to the most intense and passionate, interspersed with neutral and earthy tones."

Within the new fabric collection, metallic geometries, chiné floral patterns, and nature-inspired textures combine with theatrical sets and calligraphic artistry for a collection that enhances the sensual sphere. A true ode to femininity with the new gothic style with a dark aesthetic but equally balanced by that touch of essentiality and attention to detail.

"As intangible as a second skin, Sensitive Fabrics offer breathability, freshness and lightness," Eurojersey said". Delicate and super comfortable they feature three-dimensional stretch for a perfect fit. Innovative, inimitable and pilling-free, they are the undeformable and irreplaceable fabrics for the pleasure of the wearer, adapting to the body and lending sophistication to every undergarment."

Investment

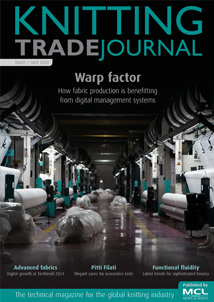

Eurojersey says it is also continuing to implement its a new investment plan, announced earlier this year, which will see the completion of a high-tech, vertically integrated production facility for its Sensitive fabrics.

Over the course of 2022, Eurojersey has earmarked around €9 million of capital expenditure which will mostly be used to upgrade its manufacturing facilities across both the knitting and dyeing & finishing departments.

“The areas involved concern the completion of the new Atelier division in the Knitting department, which, when fully operational, will have 12 warp knitting machines, the development of the Dyeing project with the implementation of new dyeing machines with the aim of reducing water use by 15 per cent, and the inclusion of new machinery for the preparation and finishing of fabrics,” said Andrea Crespi, General Manager of Eurojersey.

The new investment follows a strong 2021 for the warp knit specialist in which the company increased its turnover by 27.5 per cent compared to the previous year.

"Not only that, we can also say that we are up 10 per cent compared to 2019, having closed 2021 with a turnover of €80 million," added Matteo Cecchi, sales director at Eurojersey. "The priority objective now for 2022 is to consolidate the results achieved and aim for a further increase of 5 per cent on the previous year."

Eurojersey makes its warp knitted stretch nylon fabrics in its fully integrated facility in Varese, north of Milan. In 2019, it became the first textile company to declare its Product Environmental Footprint (PEF), having been awarded PEF 010/19 certification by Certiqualit.

The PEF method to evaluate the environmental footprint of its activity was done by measuring 16 indicators involved in the analysis, including: the energy footprint, the carbon footprint, the water footprint, eco-toxicity, the eutrophication of freshwater and seawater, the deterioration of lakes and forests caused by acidic emissions.

On evaluating the water footprint, which determines the impoverishment of water resources by human activities carried out in a given area, the environmental impact of Eurojersey’s production of one square metre of dyed fabric was the equivalent of 1.3 – 4.1 cubic metres of water. If we consider that the footprint determined by one 0.75 litre bottle of still wine is equivalent to 1.27 cubic metres of water, its impact is therefore comparable to the environmental footprint of one square metre of fabric.

The carbon footprint, which measures the impact of greenhouse gas emissions on climate change, has shown that one square metre of dyed fabric has produced an environmental impact ranging from 1.01 to 2.77 kg of CO2eq. The footprint of one kg of pasta is equivalent to 2.11 kg of CO2eq. The energy footprint of Eurojersey has evidenced that one square metre of dyed fabric has produced from 17.28 to 47.07 MJ. Such an impact is comparable to that associated with a Euro 5 vehicle covering a distance of 10 km equal to 49.1 MJ.

These savings are all part of the company’s noted commitment towards sustainability, Eurojersey says, adding that there has also been an annual saving of 4,000 metres of cellophane and 9,000 cardboard packaging tubes due to these efforts.

"Eurojersey Spa is at the top of the international textile industry in the field of warp-knitted technical fabrics, and represents Made in Italy style and creativity interpreted by its Sensitive Fabrics," the company added. "Thanks to an entrepreneurial strategy that combines innovation and constant attention to quality with a sustainable development its large-scale production, as well as promoting continuous economic investments related to the fine-tuning of the production process, the company has a growing turnover.

"The constant search for quality, the avant-garde factory, the efficiency and productivity with a single plant with a completely vertical cycle, from knitting to dyeing, finishing and printing; these are all elements of excellence with which Eurojersey has not only consolidated its client portfolio, but has also acquired new important ones in the Italian and International fashion sectors."